Industrial Robotic Machining Systems

Industrial Robotic Machining Systems for Next Level Manufacturing

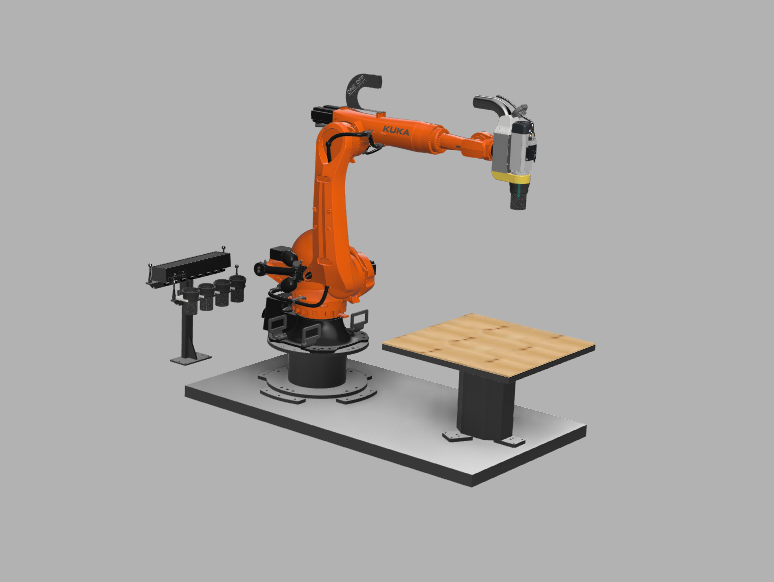

Level up your shop’s capabilities with a One Off Robotics industrial robotic machining system. Our advanced 6+ axis robotic milling cells deliver unmatched speed, flexibility, and a massive working envelope far beyond what traditional gantry CNC machines can offer.

Each system comes standard with a powerful 10 HP spindle capable of machining foam, wood, wax, resins, composites, and stone. With an 8 station automatic tool changer and built in tool calibration, you can queue multiple toolpaths seamlessly, eliminating the need to reload files.

Our standard robotic machining cell has a 2.7 meter reach and a 55 m³ working area, offering more capacity than conventional CNC machines. For larger applications, systems are easily expandable with a linear rail or two-axis positioner to meet your specific production needs.

As with all One Off Robotics machining systems, every setting is at your fingertips with the custom user interface on the KUKA smartpad. Systems include the robot, spindle, and tool change rack with precision calibration performed at installation for immediate confidence in accuracy. Expand your system with options like a two axis positioner, linear rail, touch probe, dust collection, or automated self calibration.

Key Features of Our Robotic Machining System

Large work envelope with expandable reach via linear rail and positioner

High accuracy machining with automatic calibration and smartpad UI control

Automatic 8-station tool changer with automatic calibration for seamless workflows

10 HP spindle capable of milling foam, wood, composites, stone, and more

6+ axis robotic milling flexibility for complex geometries beyond traditional CNC

Robotic Machining System Specifications

This represents our standard configuration. Larger robots and higher-powered spindles are available depending on project requirements.

Base Robot:

Built on the KUKA KR210 R2700 High Accuracy, this 6-axis robotic platform delivers the precision, reach, and repeatability required for advanced robotic machining applications

Power Supply:

Operates on 480V, 3-phase, 50A input power for consistent industrial performance.

Space Requirements:

Standard system requires a 12’ x 16’ x 12’ work envelope, providing room to machine oversized parts and complex designs.

High-Speed Milling Spindle:

Equipped with a 10 HP high-speed spindle capable of machining foam, wood, wax, resins, composites, aluminum, and stone.

Automatic Tool Changer:

Includes an 8-station automatic tool rack with tool length calibration, enabling seamless multi-tool machining without manual setup.

Available Software Integrations:

KUKA PRC, Autodesk Fusion 360, Powermill, Ency, SprutCam, RobotMaster.

Materials Supported:

Foam, wood, wax, resins, composites, aluminum, stone.

Training and Support:

All systems include in-person training at installation. One Off Robotics provides on call support to ensure long-term success and system reliability.

Optional Add-Ons:

Linear rail for extended reach

Two-axis positioner for complex geometries

Touch probe for enhanced precision

Tool calibration system for accuracy during production

Through the arm dust collection system

Want to learn more about robotic CNC machining?

Check out our knowledge base article at the link below for an in-depth discussion of robotic machining applications.