Dual Blue™: Laser Additive Manufacturing - Wire and Powder in One Platform

The Dual Blue™ system is a powerful blue laser additive manufacturing platform that supports wire, powder, or hybrid deposition all in one machine. Designed for industrial-scale production, DualBlue delivers unmatched flexibility, precision, and performance for demanding metal AM applications.

Key Features of Dual Blue™ Laser Additive System

Leveraging One Off Robotics’ full technology stack, the Dual Blue system brings together proven laser wire and laser powder additive manufacturing into a single, integrated platform. Purpose-built for high-performance metal AM, it combines large-format capability, advanced thermal control, and real-time process monitoring to meet the most demanding industrial applications.

-

Dual Blue combines Laser Wire Additive Manufacturing (LWAM) and Laser Powder Additive Manufacturing in a single machine switch between wire, powder, or hybrid deposition with no hardware changeover.

-

Equipped with advanced blue laser sources for higher absorption efficiency in reflective metals like copper, titanium, and nickel, enabling better quality, speed, and material flexibility.

-

Industrial grade rotary positioner supports large format parts with precision movement and robust part handling ideal for aerospace, defense, and energy sectors.

-

Engineered for production environments, Dual Blue delivers consistent results across large build volumes with near net shape capabilities and reduced post processing.

-

Includes real-time thermal imaging, layer tracking, and closed-loop quality feedback through One Off’s proprietary software suite ensuring each layer meets spec.

Why Choose a Blue Laser for Additive Manufacturing

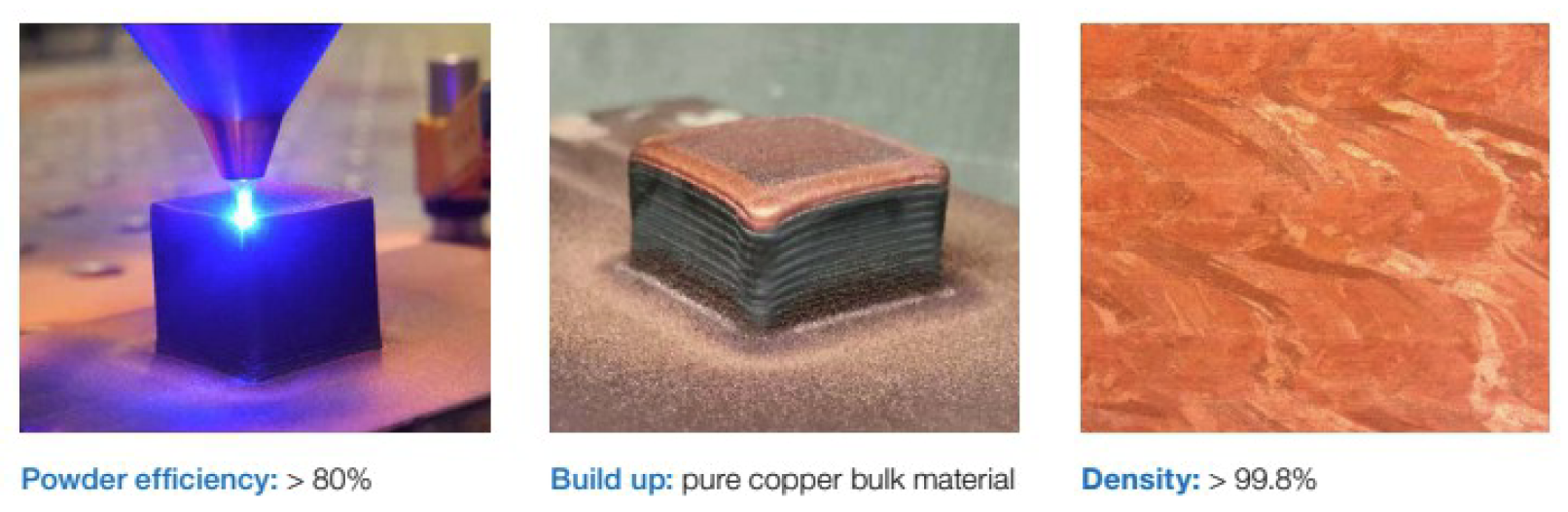

Blue lasers deliver significantly higher absorptivity in reflective metals such as copper, aluminum, and gold compared to traditional infrared (IR) lasers. This makes blue laser additive manufacturing the superior choice for applications requiring precise energy input, cleaner melt pools, and better material compatibility.

With Dual Blue, manufacturers gain the flexibility to process high-value materials that are difficult or inefficient to print using IR-based systems. Whether you're working with Cu-ETP, Al, or other thermally reflective metals, blue laser technology ensures better energy coupling, faster deposition, and more consistent results.

Key Advantages of Blue Laser AM:

Enhanced printing quality for copper, aluminum, and gold

Reduced spatter and defects through stable melt pool formation

Lower power requirements due to higher absorption efficiency

Expanded material capabilities in high-performance industries

Industrial Blue Laser Additive Manufacturing Technical Specs

-

One Off Robotics’ Dual Blue system can be configured with Laser Wire Additive Manufacturing (LWAM), Laser Powder Additive Manufacturing, or both with a single laser source. Easily switch between wire, powder, or both without reconfiguration, making it one of the most flexible metal AM systems on the market.

-

Equipped with a high-power (2kW-6kW) blue laser (~450 nm), Dual Blue is optimized for high-efficiency printing of reflective and high-performance metals.

Compatible materials include:Copper (Cu, Cu-ETP)

Aluminum

NiBrAl

Inconel

Titanium

Steel

Nickel alloys

Gold

-

The system features a 10,000 lb industrial rotary positioner, paired with a multi-axis robotic arm for full part accessibility and high precision motion.

Key specs:Build Envelope: Customizable for large-format metal parts. Standard is 2m³

Axes: Multi-axis robot with 2-axis positioner

Ideal for producing complex, high-value parts in aerospace, defense, and marine industries.

-

Dual Blue™ is designed for seamless integration into industrial environments.

Infrastructure details:Power Input: 480V, 3-phase, 100A

Cooling: Integrated active cooling system for lasers and optics

Footprint: Flexible layout options to fit standard industrial floorplans

-

Dual Blue includes One Off Robotics’ proprietary laser additive manufacturing software suite, offering full system control, automation, and quality assurance tools.

Key capabilities:Automated build plate calibration and TCP calibration

Integrated thermal imaging and melt pool monitoring

Closed-loop control for real-time quality correction

Full process logging and data recording

Perfect for both high mix and production scale additive workflows.

Additive Manufacturing with Copper and its Alloys

At least 5 times higher build-up rates compared to IR lasers

Stable process for AM with pure copper and alloys like Copper Nickel or NiBrAl

About 20% more efficient process for Stainless steel Ni- & Co-alloys