Nomad: Field-Deployable Metal Additive

One Off Robotics full wire-arc additive capabilities are now available in a rugged, mobile package. Housed in a reinforced 20’ shipping container, Nomad features a climate-controlled print enclosure and operator workspace. Designed for generator power via a single-point electrical connection, Nomad maintains a stock container appearance for simplified logistics.

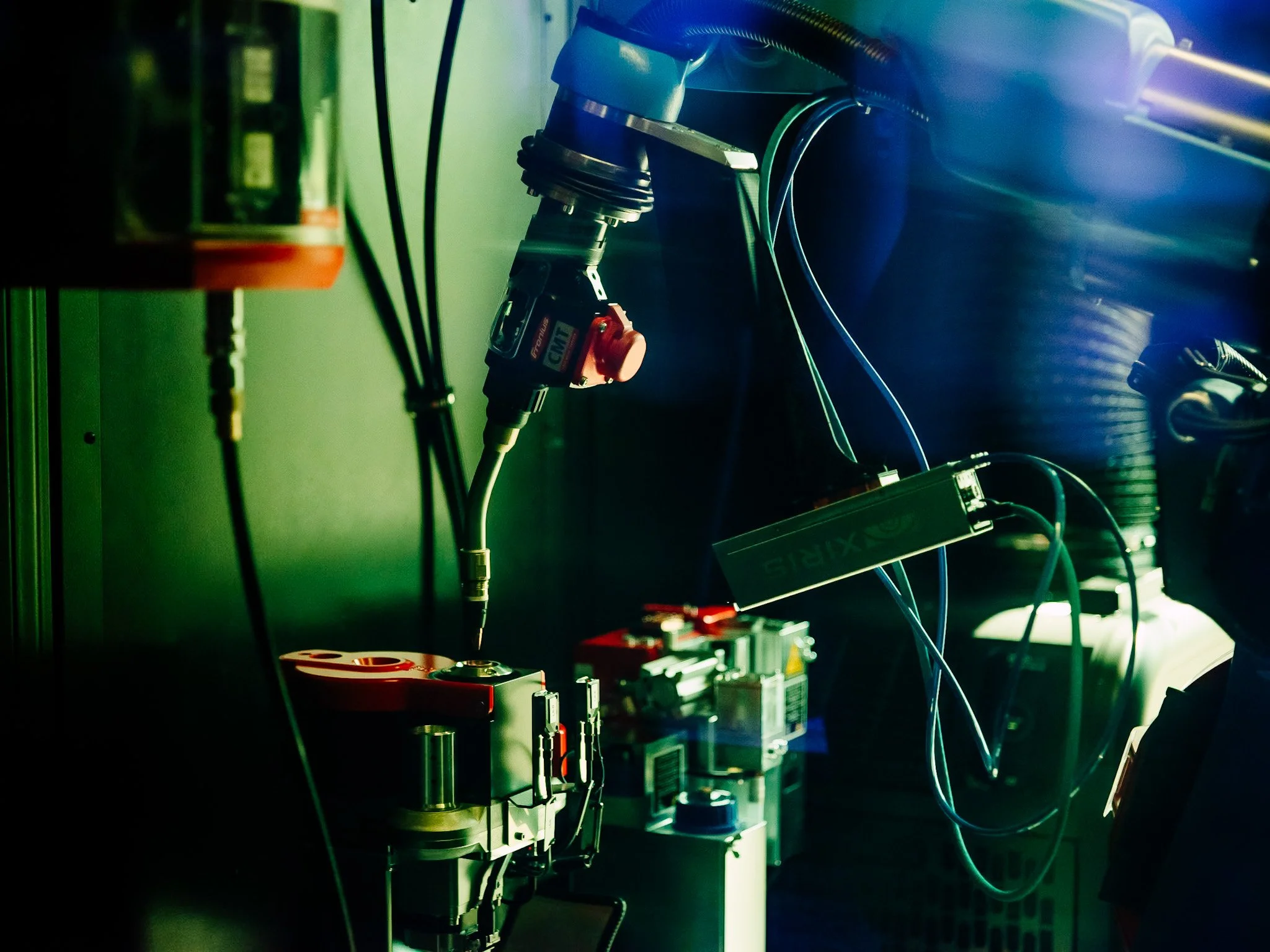

Field‑Ready Deployable WAAM System - Rugged, Intelligent & Fully Integrated

Nomad brings industrial Wire Arc Additive Manufacturing into a rugged, containerized format. Designed for remote deployment, it supports full metal 3D printing capabilities wherever power and logistics allow.

-

Achieve 4 kg+/hr deposition using MIL‑Spec wire in remote environments.

-

Automatically detects the build plate and calibrates the robot torch enabling fast, precise setup without manual input.

-

Integrated sensors continuously assess bead height, interpass temperature, and melt pool dynamics to make live adjustments.

-

Maintain consistent layer height and thermal integrity throughout the build with patented real-time controls.

-

Nomad autonomously changes tips, reams nozzles, and trims wire mid-print, keeping operations running anywhere in the world without interruption.

Production-Ready - Today, Deployable WAAM Systems

Nomad™ delivers field-capable Wire Arc Additive Manufacturing. It is more than a field tool. It’s a self-sustaining digital factory, engineered to produce critical components wherever and whenever they’re needed.

Rugged Containerized WAAM System, Protected in Transit

Heavily reinforced container protects components during transit

Single-point electrical connection with power filtration for rapid, reliable, and secure setup

Dedicated climate-controlled operator workspace for optimal comfort

Includes spare parts, tools, and materials for uninterrupted operation

Field-Deployable WAAM built on Monarc™

Nomad includes the complete feature set of our flagship Monarc™ platform:

Patented Real‑Time Corrections for WAAM Accuracy: Enables dynamic adjustments during Wire Arc Additive Manufacturing to maintain geometric fidelity.

Broad Material Compatibility: Prints with steel, titanium, Inconel, aluminum, and more using standard welding wire.

High-Resolution WAAM Prints Reduce Machining Time: Clean, near-net shapes minimize post-processing.

Automated Billet & Stock Printing: Print rectangular or round forms without slicing software, and ready for machining.