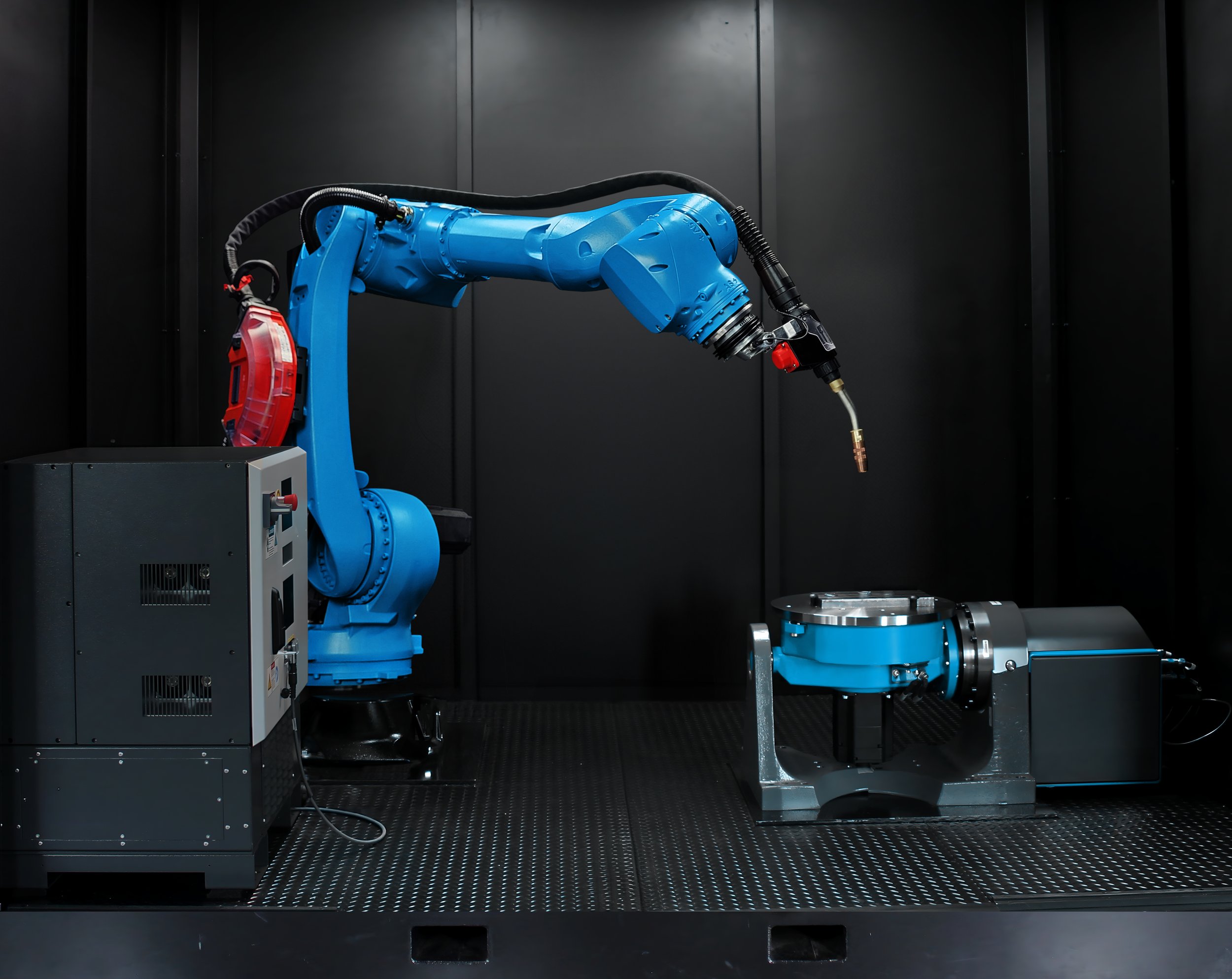

Monarc™: Industrial WAAM 3D Printing System for Metal Manufacturing

Industrial WAAM Platform: Robust, Intelligent, Fully Integrated

Monarc™ is a production-ready Wire Arc Additive Manufacturing (WAAM) system designed for high-throughput metal 3D printing. Built with industrial-grade hardware, real-time monitoring, and automated calibration, it delivers consistent results with minimal operator oversight. Compatible with steel, titanium, Inconel, aluminum, and more, Monarc adapts to the demands of defense, aerospace, and advanced manufacturing environments.

The Monarc platform is built with the best hardware in the world alongside our custom software and features developed from years of robotic additive experience to ensure the most capable and production ready system on the market.

Industrial WAAM Platform: Robust, Intelligent, & Fully Integrated.

Monarc™ is engineered for high-speed Wire Arc Additive Manufacturing (WAAM) in demanding metal 3D printing environments. It blends automated calibration, real-time monitoring, and process control to deliver reliable, production-grade performance.

-

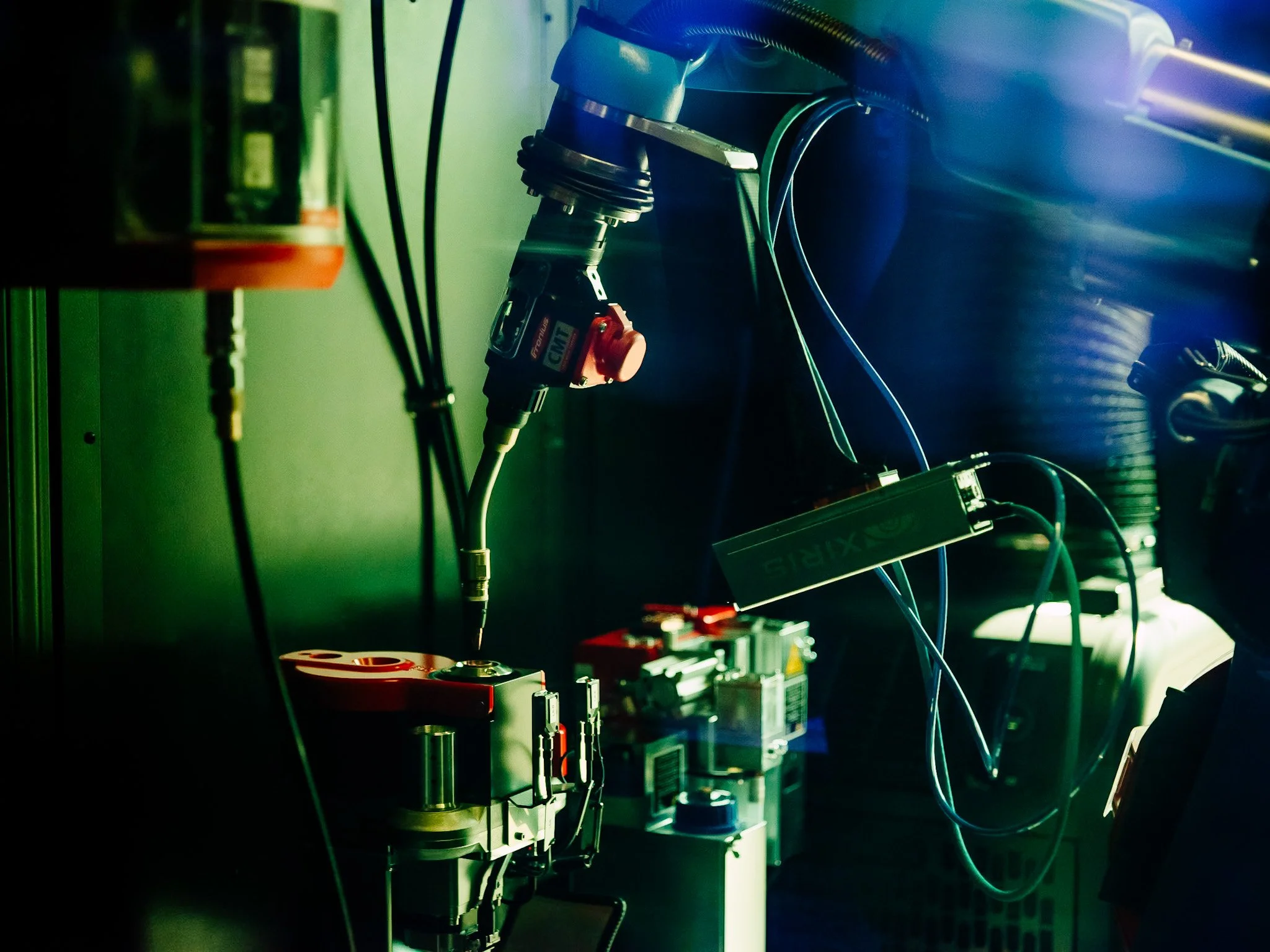

Achieves 4+ kg/hr using mil-spec wire and industrial arc control

-

Automatically detects the build plate and calibrates the robot torch enabling fast, precise setup without manual input

-

Live sensor feedback on bead height, thermal state, interpass temperature, and melt pool dynamics to make live adjustments.

-

Maintain consistent layer height and thermal integrity throughout the build with patented real-time controls

-

Autonomously changes tips, reams nozzles, and trims wire mid-print, keeping operations running without interruption.

Monarc™ WAAM System Features for Industrial Metal 3D Printing

Patented Real‑Time Corrections for WAAM Accuracy: Enables dynamic adjustments during Wire Arc Additive Manufacturing to maintain geometric fidelity.

Broad Material Compatibility: Prints with steel, titanium, Inconel, aluminum, and more using standard welding wire.

High-Resolution WAAM Prints Reduce Machining Time: Clean, near-net shapes minimize post-processing.

Automated Billet & Stock Printing: Print rectangular or round forms without slicing software, and ready for machining.