Direct Energy Deposition (DED): Metal Additive Experts

One Off Robotics delivers production-ready metal additive solutions. Eliminate long lead times, reduce waste, and simplify complex supply chains by manufacturing in-house.

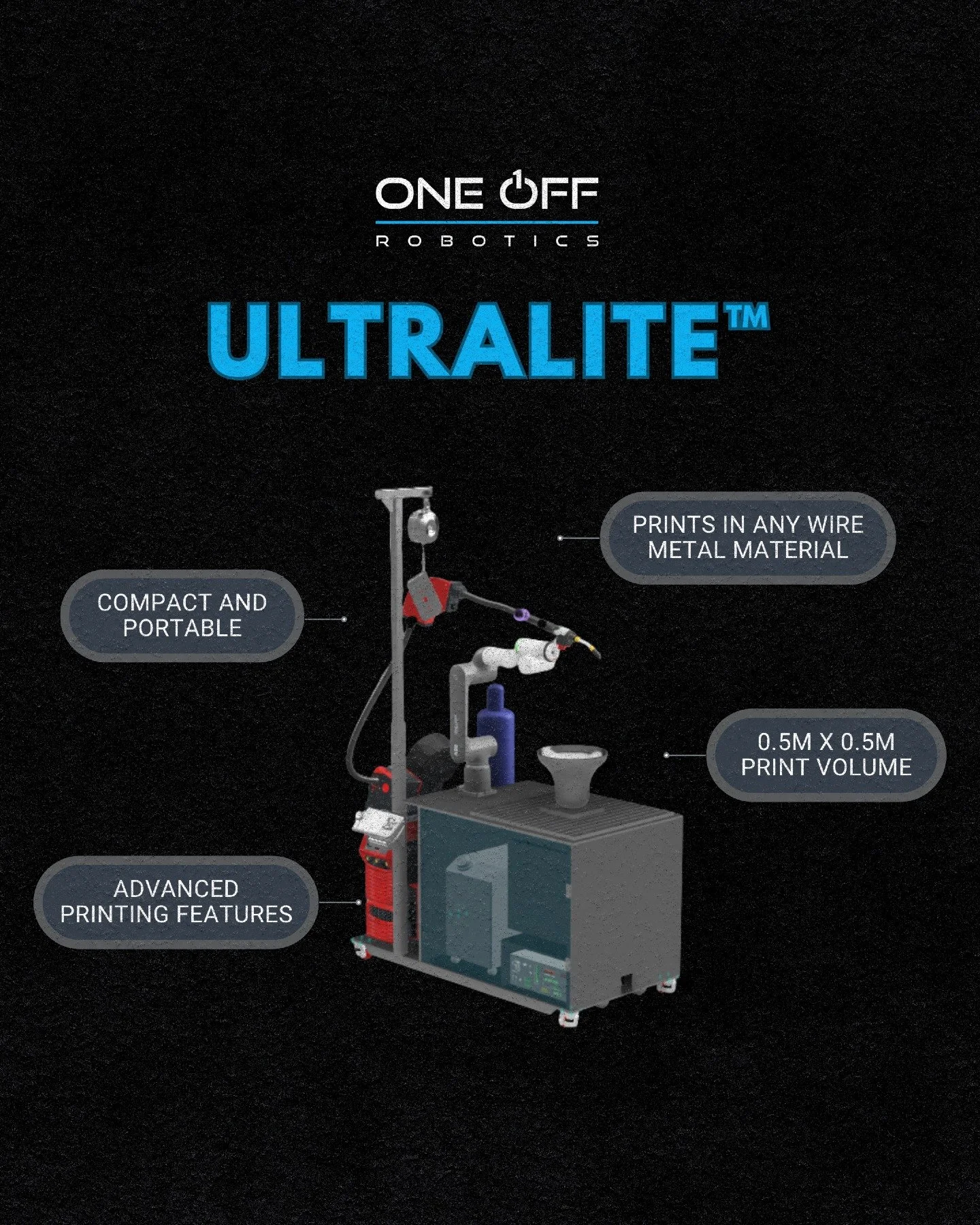

Nomad: Field-Deployable WAAM

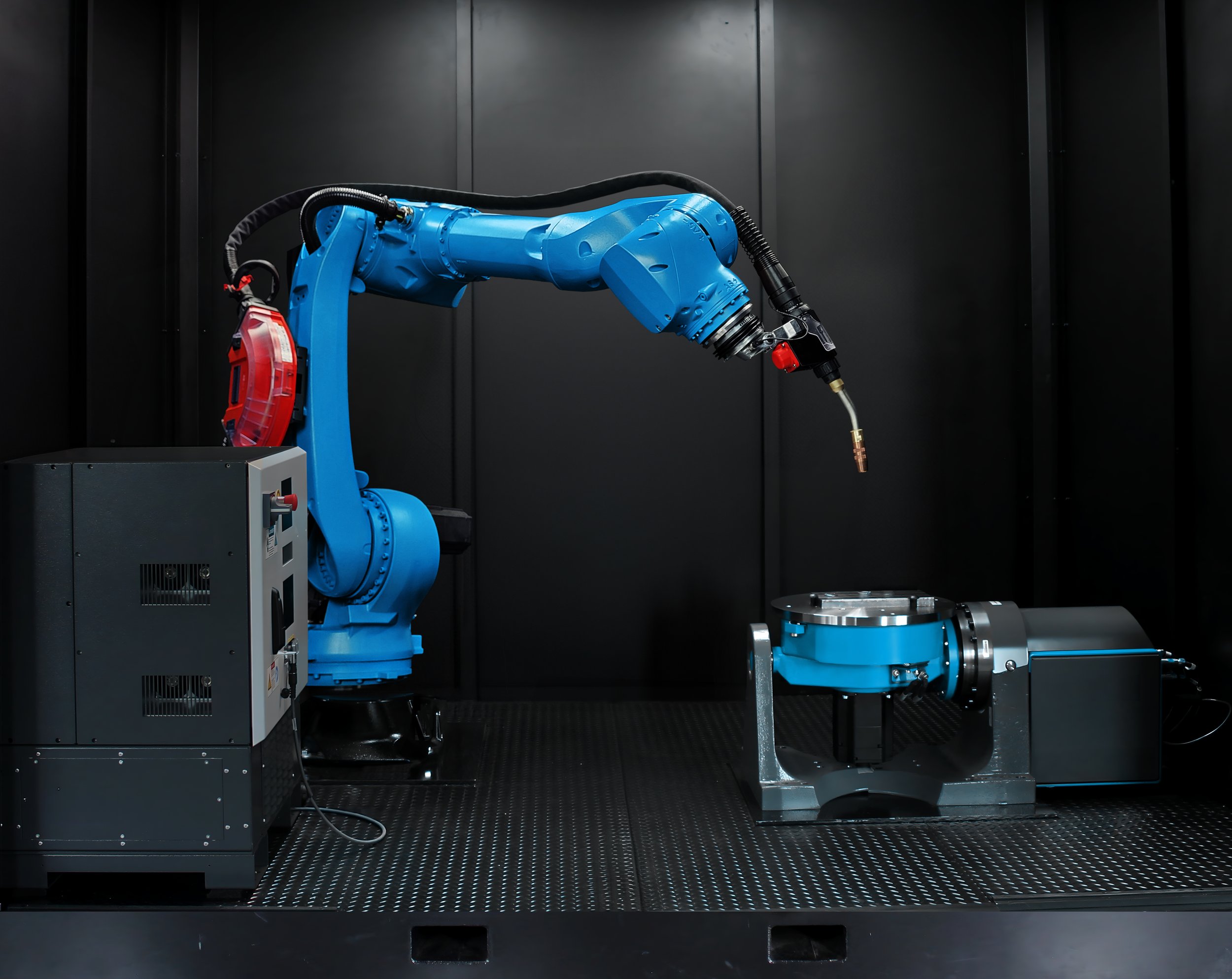

Monarc: Production WAAM Platform

Direct Energy Deposition Printing Service

Can’t wait to get a system? Send us your parts for prototyping and printing at our Chattanooga manufacturing facility.

Offerings

-

Rapid Part Printing

We deliver certified-grade metal parts in a fraction of the time and cost of traditional methods. Get started quickly without the need to purchase a machine.

-

Production-Ready Systems

Our systems integrate the most trusted hardware and our own proprietary software into user-friendly interfaces that turbocharge your manufacturing workflow.

-

Custom Tailored Systems

We offer full-service solutions to bring your idea to life from design concept to deployment and on-site training.

Follow us on Instagram