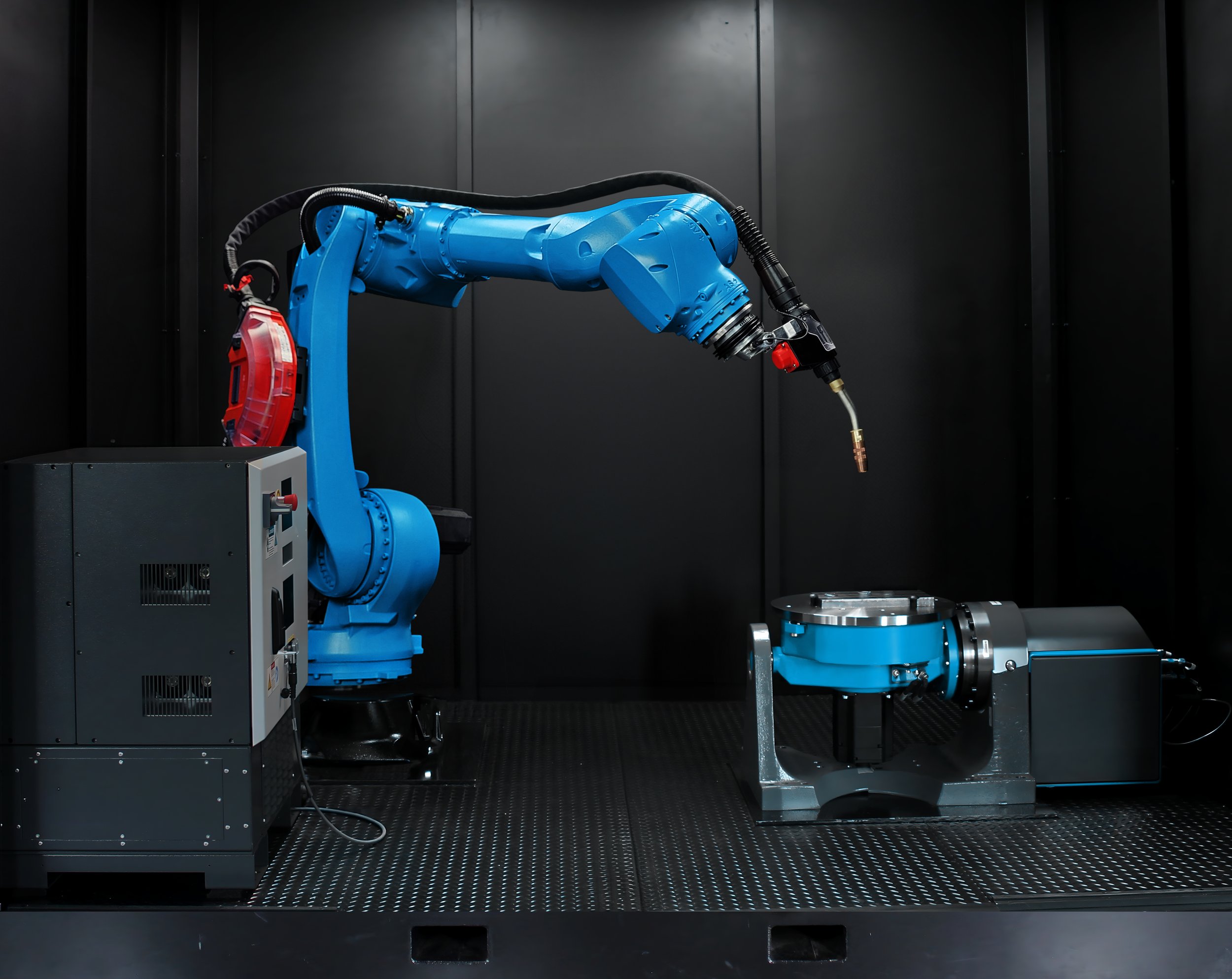

PART PRODUCTION

as a service

Transform Your Part Production with WAAM

Scalable, High-Performance Metal Additive Manufacturing

At One-Off Robotics, we specialize in Wire Arc Additive Manufacturing (WAAM), a cutting-edge metal 3D printing technology designed to produce large, high-strength metal components faster and more cost-effectively than traditional methods.

Our robotic WAAM systems offer a scalable, material-efficient solution for aerospace, defense, energy, marine, and industrial sectors—delivering fully dense metal parts with exceptional mechanical properties.

Industries & Applications

Aerospace & Defense

✔ Lightweight, High-Strength Structures – Titanium & Aluminum components for aircraft and space systems

✔ Turbine & Engine Parts – High-temperature Nickel alloys (Inconel 718, 625) withstand extreme conditions

✔ Satellite Components – Rapid prototyping and mission-specific metal parts

Equipment & Automotive

✔ Custom Metal Tooling & Fixtures – High-strength parts for manufacturing & assembly

✔ High-Performance Racing Components – Custom aluminum and titanium structures

Energy & Power Generation

✔ Gas & Steam Turbine Blades – High-temperature Inconel 718 and Stainless Steel 316L components

✔ Heat Exchangers & Piping – WAAM-printed corrosion-resistant structures for oil & gas and renewables

Marine & Shipbuilding

✔ Propellers & Structural Reinforcements – Large Nickel Aluminum Bronze (NAB) and Stainless Steel 316L parts

✔ Corrosion-Resistant Marine Hardware – Durable, seawater-resistant components

Why Choose WAAM

-

Print components that exceed the size limitations of conventional metal 3D printing.

-

2-8 kg/hour, enabling faster production cycles.

-

WAAM uses 95% of input material, reducing waste.

-

No molds or dies needed, cutting lead times.

-

Custom, low-volume production without high setup costs.

-

WAAM-printed parts offer excellent fatigue resistance and mechanical integrity.

WAAM Materials

We use High-Performance Metal Wire Feedstock for Durability and Strength

Aluminum Alloys – Lightweight & Corrosion-Resistant

Titanium – High Strength & Low Weight

Nickel-Based Alloys – High-Temperature Performance

Steel Alloys – Structural & Marine Durability

Copper & Nickel Aluminum Bronze – Electrical & Marine Strength