HARDWARE

Wire Arc Additive Manufacturing (WAAM)

WAAM represents a transformative approach in the additive manufacturing landscape, leveraging the principles of arc welding to fabricate metal components layer by layer. This process utilizes an electric arc as the heat source and metal wire as the feedstock, combining them to create large-scale parts with substantial material savings.

WAAM has revolutionized the manufacturing process by offering a cost-effective and efficient alternative for producing metal parts, especially suitable for industries like aerospace, automotive, and shipbuilding. The technique's adaptability in handling various metals, along with its scalability, makes it an attractive option for applications requiring large metal components with robust mechanical properties.

Our Fronius WAAM end-effectors are the industry standard and have metal deposition rates averaging 4 Kg/hr.

-

WAAM uses standard welding equipment and wire, making it a more affordable option compared to other additive manufacturing methods that require specialized materials and machinery.

-

This method produces near-net-shape objects with minimal material wastage, as it adds material only where needed.

-

WAAM is well-suited for creating large components due to its relatively high deposition rates and the ability to handle large build volumes.

-

It can process a wide range of metals, including steel, titanium, and aluminum alloys, providing flexibility in applications across various industries.

-

The process can enhance certain mechanical properties of the manufactured parts, such as strength and toughness, due to the inherent metallurgical processes involved in welding.

Wire-Laser Additive Manufacturing (WLAM)

Wire-Laser Additive Manufacturing (WLAM) is at the cutting edge of additive manufacturing technologies, employing a high-precision laser to melt metal wire, thereby depositing it layer by layer to form complex geometries. This innovative process is distinguished by its ability to precisely control the melt pool, resulting in components with superior surface finish and mechanical properties.

WLAM enables the fabrication of parts from advanced materials, including high-strength alloys and refractories, which are often challenging to process using traditional manufacturing methods. Its high degree of precision, coupled with reduced material waste and energy consumption, positions WLAM as a pivotal technology for industries pursuing high-performance components with intricate designs, such as aerospace, medical implants, and energy.

One-Off Robotics offers multiple WLAM end-effector solutions supporting multiple laser wavelengths and variable power consumption, with deposition rates up to 10 Kg/hr.

-

WLAM offers higher precision and surface quality compared to WAAM, due to the focused laser beam providing better control over the melt pool.

-

The rapid cooling rates associated with the laser can lead to finer microstructures in the manufactured parts, potentially improving their mechanical and physical properties.

-

Like other additive manufacturing processes, WLAM allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional subtractive methods.

-

The focused nature of the laser beam results in more efficient use of energy, reducing the overall energy consumption of the manufacturing process.

-

WLAM can process high-performance materials, including refractory metals and advanced alloys, expanding its applicability to industries requiring materials with exceptional performance characteristics.

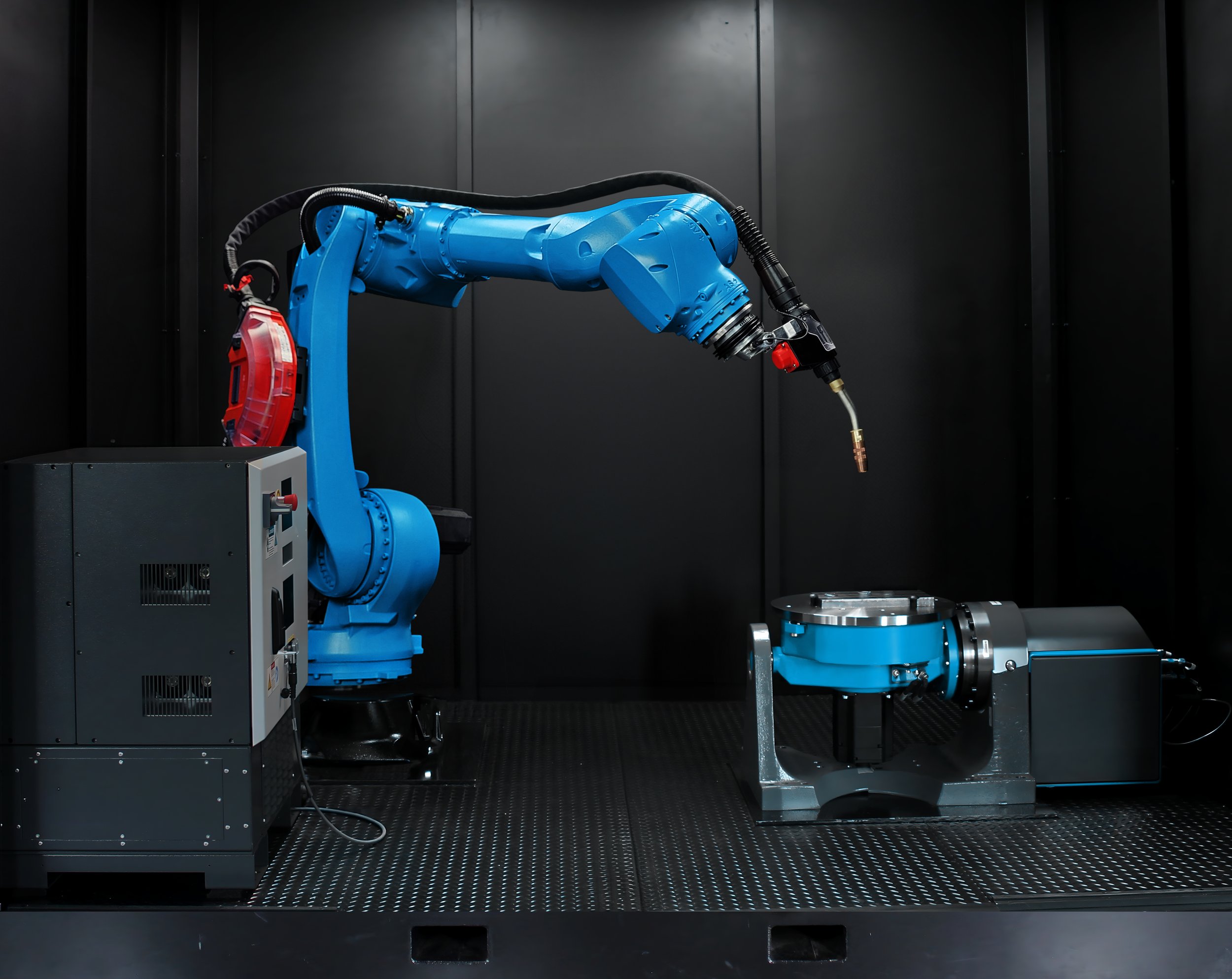

Robots & Positioners

One-Off Robotics uses 6-axis industrial robots, optional linear rails, and 1 or 2-axis positioners designed specifically for demanding environments and commercial applications.

Our robots are specially designed for flexible use cases and scenarios, and can communicate extensively with a variety of external systems.

Data Sensors

Real-time temperature measurement with an exceptionally clear view of your process and melt pool, even in harsh environments where vision would typically be obscured by smoke, fumes, and spatter.

Thermal Imaging

Point clouds use a 3D scanner to capture a collection of spatial data points to recreate the shape of the physical print, making measurement and analysis possible at any location.

Point Cloud Scanning

Machine tool inspection probes play a key role in achieving precision throughout the manufacturing process. Our precision measurement devices provide automated workpiece set-up, in-process control, and part verification.

Touch Probing

Non-invasive acoustic monitoring is an effective addition to optical or laser measurements. The combination of visual and sound monitoring in additive manufacturing improves operators’ abilities to fine tune and monitor the manufacturing process.

Audio Data Collection

Accessories

Robotic tool changers allow for the use of multiple end effectors. Packages include tool stands, robo-couplers sized for your application, and all necessary sensors and programming.

Automated Tool Change

For large prints that require many hours of continuous printing we offer automated tip changeovers. This process allows for continuous uptime without print failure due to wear-item fatigue.

Automated Tip Change

Heat accumulation can significantly affect the molten pool shape and the forming quality of metal prints. Forced air cooling offsets this while also allowing for added efficiency by increasing the overall deposition rate and decreasing the interlayer dwell time.

Forced Air Cooling

One-Off Robotics has a long history in advanced, high accuracy, robotic machining. Having the option to do in-situ part machining can save valuable time in the process of metal additive fabrication.

Robotic Print Decking

Enclosure

-

Our smallest cell enclosure has a footprint of 8x10x8ft

-

Strong but lightweight cell enclosures can be moved easily with a forklift.

-

FDA approved laser safe enclosure.

-

All enclosures can include fume containment and air evacuation.

-

All One-Off Robotics additive manufacturing cell enclosures are plug-in ready